.jpg)

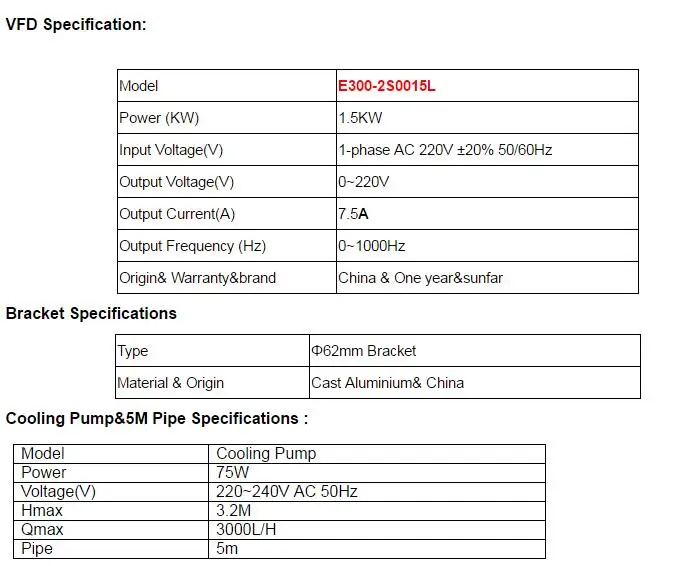

1.2KW Spindle Motor Water-cooling 60000RPM High Speed ER11 + 1.5KW VFD Inverter Driver 1phase 220V CNC Router Milling Drilling

Package Included :

1 x 1.2KW Spindle Motor

1 x 1.5KW VFD Inverter Driver

1 x Mount Bracket

1 x Water pump & Pipe Kit

Providing the default Nut ER11 and Collet 6mm, if not please do contact us for a better solution.

Specifications

|

Model Type |

GDZ62-1.2 Constant Torque |

|

Rev(rpm) |

60000rpm |

|

Power(kw) |

1.2kw |

|

Diameter&length |

62*202mm |

|

Voltage(V) |

220v |

|

Current(A) |

4.5A |

|

Frequency(HZ) |

1000Hz |

|

Cool |

water cooled |

|

Bearing type |

2*7002C P4 DT & 2*7000C P4 DT |

|

Lubricate |

grease |

|

collet(mm) |

ER11 |

|

repair time |

bearing(half year), spindle(one year) |

|

Runout |

0.01-0.02mm |

|

Notice |

Spindle motor must be inverter VFD output, cannot directly connect power supply |

|

Brand |

changsheng |

Kindly note:

Motorized spindle motors are matched with inverters, choosing inverters should be according to the current, voltage, and frequency of motorized spindle motors.

1.Setting the inverter must firstly set up the basal frequency, its basal frequency is based on the highest frequency of motorized spindle motor, if not setting the basal frequency (the factory setting is 50Hz),the motorized spindle motor would burn out once start running;

2.the highest frequency, break frequency and the corresponding voltage also should be set according to the curve on the operating instruction; setting the current of the inverters is also based on the rated current of motorized spindle motor;

3.the overcurrent is 120% of rated current; overload tripping is 100%, time is 5s;

4.carrier frequency is set by the power of spindle motor,8kHz for less than 10KW motorized spindle motor, 5kHz is for more than 10KW spindle motor;

5.the acceleration time and deceleration time are 10s and 20s respectively, if starting current exceed the rated current and need protection, it should extend the acceleration time.

6.I/O lack-phase protection also should be set above the function of protecting inverters and motorized spindle motors.

7.Connecting the inverter and the three-phase power of spindle motor, solder the inverter three-phase power cord on the plug 1(U1),2(V1),3(W1), plug 4 is ground wire. Then the inverter is connected with the external power supply and start work, then to check whether the rotation direction of spindle motor is consistent with its indication direction, if inconsistent, immediately shut down and change two wire on the three-phase power supply of connecting inverter and motorized spindle motor. The motorized spindle motor is prohibited running in the wrong rotation direction.

8.Power lines should be taken waterproof and shielding measures. The connection between motorized spindle motor and inverter should not exceed 25m.When the power cord of the water-cooled spindle motor connects the terminal block, it must be bent into U shape and fixed on the bottom of the terminal block and then connect, so that can protect the condensed water of the power cord into the terminal block.

9.Another, use shielding power lines to prevent its interference to inverter.

Tell us what you think about this item, share your opinion with other people. Please make sure that your review focus on this item. All the reviews are moderated and will be reviewed within two business days. Inappropriate reviews will not be posted.

Have any question or inquire for this item? Please contact us. Our customer representative will get back shortly.